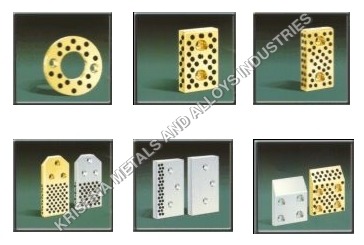

Bush Bearings

Bush Bearings Specification

- Weight

- Varies as per size

- Material

- Bronze / Brass / Gunmetal / Phosphor Bronze / Cast Iron / Sintered Metal

- Ball Bearing Type

- Plain Bush Bearing

- Bushes Type

- Solid, Flanged, Split, Sintered, and Sleeve Bushes

- Structure

- Cylindrical and Flanged Type

- Seals Type

- Open / Without Seals

- Number Of Rows

- Single Row

- Load Capacity

- Up To 30,000 N

Bush Bearings Trade Information

- Payment Terms

- Cheque

- Delivery Time

- AS PER REQUIRMENT Days

- Sample Available

- Yes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Bush Bearings

We, at our end have all the capabilities from sourcing of raw materials to quality inspection, and this make us one of the recognized manufacturers and exporters of Bush Bearings. Available in different finish options and sizes, all these bearings are used in many machines. Manufactured in compliance with the industrial standards using certified quality of raw materials, all these Bush Bearings are reckoned in market for their accurate dimensions, corrosion resistant surface and durability.

Versatile Profiles for Varied Applications

Our bush bearings are crafted to suit round and custom profiles, enabling compatibility with an array of industrial sectors such as automotive, agricultural equipment, and machinery. The flexibility in profile ensures seamless integration into both standard and specialized engineering designs, enhancing system adaptability and effectiveness.

Premium Material Choices and Corrosion Resistance

Customers can select bush bearings manufactured from quality materials like bronze, brass, gunmetal, phosphor bronze, cast iron, or sintered metal. This diversity allows you to match the optimal corrosion resistance and mechanical properties required for your operation, prolonging bearing life and reducing maintenance interruptions.

Precision Tolerances and Reliable Operation

Designed to H7 tolerances or as per custom requirements, our bush bearings guarantee precision fits for press or slide installations. With hardness between 60 and 90 HRB and load capacities up to 30,000 N, these components assure durability, smooth motion, and consistent performance in demanding environments.

FAQs of Bush Bearings:

Q: How do I choose the right bush bearing shape and profile for my application?

A: You should consider the specific design requirements of your equipment and the type of fit desired. Custom profiles are available in addition to round shapes, ensuring compatibility for both standard and specialized assemblies in automotive, industrial, and agricultural settings.Q: What materials are used in these bush bearings, and how does material choice affect performance?

A: We manufacture bush bearings from bronze, brass, gunmetal, phosphor bronze, cast iron, and sintered metals. Your choice affects corrosion resistance, lubrication requirements, durability, and operational environment suitability.Q: When is it recommended to use the self-lubricating type for bush bearings?

A: Self-lubricating bush bearings are ideal for applications where maintenance access is limited or frequent re-lubrication is impractical, reducing downtime and extending service life in industrial and automotive equipment.Q: Where can these bush bearings be installed, and what installation methods are available?

A: These bearings are suitable for machinery, vehicles, agricultural tools, and various engineering equipment. Installation can be done using either a press fit or slide fit, depending on the applications design requirements and operational load.Q: What is the manufacturing process for these bush bearings?

A: Our process includes precise machining, grinding to size, and custom finishing as per requirement. Quality materials are selected and processed to meet tolerance levels (H7 or custom), ensuring high performance and dimensional consistency.Q: How does the load capacity and hardness benefit my equipment?

A: With a load capacity of up to 30,000 N and a hardness range of 60 to 90 HRB, these bush bearings provide robust support and longevity for moving components, minimizing wear and extending equipment life in heavy-duty operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball & Roller Bearings Category

White Metal Bushes

Minimum Order Quantity : As per Requirement Piece

Weight : 0.6 kg

Bore Size : 25 mm

Bushes Type : Other, Plain Bush

Thickness : 10 mm

Structure : Solid Sleeve

Ahmedabad, Gujarat, India

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free